no need, if you have built hundreds of engines and you haven't figured it out yet, you might need to apply at TRD.Explain how a cam is going to break one valve spring and not affect the other 15...

FWIW, I've built hundreds of engines.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Mar 21, 2012

- Messages

- 26,697

- Points

- 1,033

Yep....one over lifting lobe.

ted@economy

in the interest of equal time

...one over lifting lobe.

I had a girlfriend like that once . Course it was no big deal back then .

FenderBumper

The "good old days" ??

I had a girlfriend like that once . Course it was no big deal back then .

Maybe it wasn't a girl afterall?

So.........lemme get this right: One lobe has more lift than the others?!!!...one over lifting lobe.

C'mon man explain it. Enlighten me. How does the cam cause one spring to break and not the other 15?no need, if you have built hundreds of engines and you haven't figured it out yet, you might need to apply at TRD.They need the help. Using different metal mixture combinations, you can control thermal linear expansion, hardness, brittleness you name it. You can make a cam, or a pushrod, or anything metal for that matter, larger, longer, when a certain temperature is applied. They said those engines were designed to run 600 miles at that particular track. They have it scienced out. Why do you think they keep track of the laps, why do you think when they miss a shift they usually blow up. Everything is right on the edge, given a certain set of parameters. This is rocket science.

Or should I just fly the

flag now?

flag now?I have already explained it three different times, and three different ways. You got your little flag flying so even that is over your head.  get ya a statics and strengths of materials book and read it, also a basic metallurgy textbook. gotta have calc three before you can make it out if you don't have that. Structural steel if you get thru those.

get ya a statics and strengths of materials book and read it, also a basic metallurgy textbook. gotta have calc three before you can make it out if you don't have that. Structural steel if you get thru those.

get ya a statics and strengths of materials book and read it, also a basic metallurgy textbook. gotta have calc three before you can make it out if you don't have that. Structural steel if you get thru those.

get ya a statics and strengths of materials book and read it, also a basic metallurgy textbook. gotta have calc three before you can make it out if you don't have that. Structural steel if you get thru those.Check your dipstick cuz yer full of sh!t. You said the cam caused ONE valve spring to break. How did the cam cause one spring to break and not the other 15?????????????????? Or are you backpedaling now and saying that the spring was defective.I have already explained it three different times, and three different ways. You got your little flag flying so even that is over your head.get ya a statics and strengths of materials book and read it, also a basic metallurgy textbook. gotta have calc three before you can make it out if you don't have that. Structural steel if you get thru those.

You might fly your bullsh!t past the parts guy at Autozone but those of us that know better know that you are FOS

While you were in Calc3 and metallurgy, I was in Ford, GM, Jeep/Chrysler school learning how to build engines and transmissions.

I think SSBob highjacked another account

FenderBumper

The "good old days" ??

So.........lemme get this right: One lobe has more lift than the others?!!!

C'mon man explain it. Enlighten me. How does the cam cause one spring to break and not the other 15?

Or should I just fly theflag now?

Really Bobby? You built hundreds of engines, right? SURELY you know that different cams can provide different lift for performance engines by changing the lobe shape (duration) and height (larger air rate). 2 valve per cylinder pushrod V8 engines have a single cam with 16 lobes, 2 for each cylinder. One bad lobe = one faulty valve operation.

C'mon, you know a single over lift lobe is possible, and it would lift the pushrod too high, which in turn would lift one side of the rocker too high. That would cause the spring side of the rocker to depress too low, causing the poppet valve to extend too far into the cylinder, causing it to meet the rising piston and even snapping the valve spring from over compression.

Absolutely. The engine in my pick up has a dual pattern camshaft, meaning more lift on either the exhaust or intake side (usually on the exhaust side due to the smaller exhaust valve.). But, there isn't one single lobe, intake or exhaust that has more lift than the other lobes. A bad lobe is one going flat, not one getting larger. A driver would be able to feel a lobe going flat. A lobe going flat is not going to cause a valve spring to fail. These engines run roller cams, which generally do not lose lobes.Really Bobby? You built hundreds of engines, right? SURELY you know that different cams can provide different lift for performance engines by changing the lobe shape (duration) and height (larger air rate). 2 valve per cylinder pushrod V8 engines have a single cam with 16 lobes, 2 for each cylinder. One bad lobe = one faulty valve operation.

C'mon, you know a single over lift lobe is possible, and it would lift the pushrod too high, which in turn would lift one side of the rocker too high. That would cause the spring side of the rocker to depress too low, causing the poppet valve to extend too far into the cylinder, causing it to meet the rising piston and even snapping the valve spring from over compression.

StandOnIt insinuated that the cam could have caused a single valve spring to break, while not affecting the other springs. I had no choice but to fly the flag

HoneyBadger

Kelsey Mitchell fan account

Tennessee Racing

Formerly Stewart Fan

I think SSBob highjacked another account

That would be what 3 now? Got more personalities than Amanda Bynes.

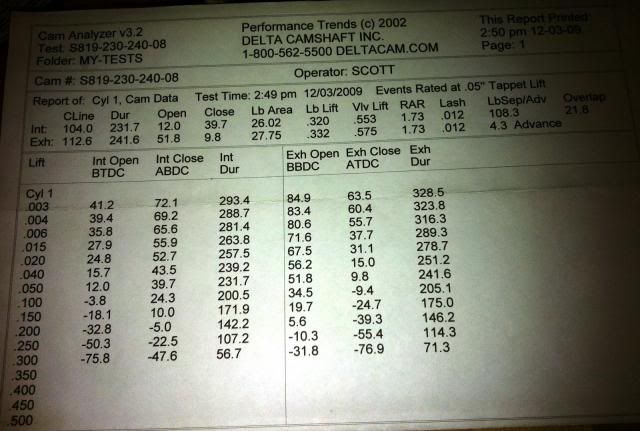

Not.I see one lobe 3/1000ths high, might bust a spring, better check it.

FenderBumper

The "good old days" ??

Absolutely. The engine in my pick up has a dual pattern camshaft, meaning more lift on either the exhaust or intake side (usually on the exhaust side due to the smaller exhaust valve.). But, there isn't one single lobe, intake or exhaust that has more lift than the other lobes. A bad lobe is one going flat, not one getting larger. A driver would be able to feel a lobe going flat. A lobe going flat is not going to cause a valve spring to fail. These engines run roller cams, which generally do not lose lobes.

StandOnIt insinuated that the cam could have caused a single valve spring to break, while not affecting the other springs. I had no choice but to fly the flag

ROFL! Dude, I said a manufacturing defect, not steel growing like a chia pet inside the engine.

Read here and see how virtually impossible it would be to have one defective lobe on a camshaft...> http://www.dragzine.com/features/shop-tours/comp-cams-shows-how-a-camshaft-is-made/ROFL! Dude, I said a manufacturing defect, not steel growing like a chia pet inside the engine.You asked how a cam could cause just one valve to fail. I answered the question.

Cams are measured and inspected as part of quality control before they leave the manufacturer. If that isn't enough, IF a camshaft had one lobe larger than the rest, it would be noticed when the valves were adjusted during engine assembly in the form of coil bind.

- Joined

- Mar 21, 2012

- Messages

- 26,697

- Points

- 1,033

Is that the same quality control as the light rods?Read here and see how virtually impossible it would be to have one defective lobe on a camshaft...> http://www.dragzine.com/features/shop-tours/comp-cams-shows-how-a-camshaft-is-made/

Cams are measured and inspected as part of quality control before they leave the manufacturer. If that isn't enough, IF a camshaft had one lobe larger than the rest, it would be noticed when the valves were adjusted during engine assembly in the form of coil bind.

Rods aren't weighed as a part of manufacturing. Final rod weight is determined and adjusted by the engine builder during the balancing process of the lower end.Is that the same quality control as the light rods?

Here are only some of my answers..Dufus here is fixated on only the cam?

This was about all the "light rods" they found:

Would have been interesting to see if it was the same rod in the same place. It could have been on the cylinder that keeps popping valve springs

This is about the Valve train...including rod and piston combo. Also what nobody knows apparently but TRD, is it the same cylinder that is failing on all the engines...this is assuming that it is.

It gets complicated, but one reason could be that they have one cylinder that is failing. they use a really weak spring, so the cam not only opens the valve, but the valve keep going deeper into the cylinder before the spring stops the valve. Gives the advantage of more duration for air/fuel to get into the cylinder, and on the other side, it opens longer to get it out. It is like having a bigger cam. downside is the piston can hit the valves if they are in there too far. So they use the lightest piston rod combo they can get away with..less stretching. If they have it isolated to only one cylinder that is causing the problem for whatever reason, not cooling as well or getting enough oil, they fudge a little on the weight, an even lighter piston, and valve, and rod? purely conjecture on my part, but they are dealing with really tight tolerances and they don't need much.

This is what I think that has Bobby doing a cam jig:

Lots of things can make a spring fail, the cam, pushrods, rocker arms, valve studs, the valve and it's keepers, piston/rod clearance, heat, geometry, and also the spring tension, or lack of it and the material it is made from. As you can see, it can be a pretty complicated problem. Not to mention the material everything is made from, thermal expansion values etc. WEIGHT

This was about all the "light rods" they found:

Would have been interesting to see if it was the same rod in the same place. It could have been on the cylinder that keeps popping valve springs

This is about the Valve train...including rod and piston combo. Also what nobody knows apparently but TRD, is it the same cylinder that is failing on all the engines...this is assuming that it is.

It gets complicated, but one reason could be that they have one cylinder that is failing. they use a really weak spring, so the cam not only opens the valve, but the valve keep going deeper into the cylinder before the spring stops the valve. Gives the advantage of more duration for air/fuel to get into the cylinder, and on the other side, it opens longer to get it out. It is like having a bigger cam. downside is the piston can hit the valves if they are in there too far. So they use the lightest piston rod combo they can get away with..less stretching. If they have it isolated to only one cylinder that is causing the problem for whatever reason, not cooling as well or getting enough oil, they fudge a little on the weight, an even lighter piston, and valve, and rod? purely conjecture on my part, but they are dealing with really tight tolerances and they don't need much.

This is what I think that has Bobby doing a cam jig:

Lots of things can make a spring fail, the cam, pushrods, rocker arms, valve studs, the valve and it's keepers, piston/rod clearance, heat, geometry, and also the spring tension, or lack of it and the material it is made from. As you can see, it can be a pretty complicated problem. Not to mention the material everything is made from, thermal expansion values etc. WEIGHT

- Joined

- Mar 21, 2012

- Messages

- 26,697

- Points

- 1,033

Nope, read the posts that dissected this ad nauseum, the rods were supposed to be of accurate weight when delivered to TRD from the manufacturer and reweighed by the engine builders, two separate quality control issues.Rods aren't weighed as a part of manufacturing. Final rod weight is determined and adjusted by the engine builder during the balancing process of the lower end.

Here are only some of my answers..Dufus here is fixated on only the cam?

This was about all the "light rods" they found:...This is about the Valve train...including rod and piston combo...

Hey *******, didn't I straighten you out yesterday?

FYI, the rod/piston combo isn't part of the valvetrain

Is Google broken on your computer??

What part don't you get?Nope, read the posts that dissected this ad nauseum, the rods were supposed to be of accurate weight when delivered to TRD from the manufacturer and reweighed by the engine builders, two separate quality control issues.

Somebody f'd up. Either way a light rod will NEVER cause valvetrain issues.

J

John c

Guest

1 time would be called an "F up" , but that many times makes them "F ups"!What part don't you get?

Somebody f'd up. Either way a light rod will NEVER cause valvetrain issues.

Correct.1 time would be called an "F up" , but that many times makes them "F ups"!

Here's a nice article on valvetrain stability. Disregard any contents that refer to flat tappet cams, NASCAR engines use roller cams.

Also, you'll see no mention of ANY lower end component with regard to valvetrain longevity, failure or stability.

http://www.aera.org/engine-professional/valve-train-stability/

Also, I was once in a NASCAR engine dyno room where tons of small block Chevy race parts were shelved. I noticed that the camshafts were larger diameter than those in production engines. The owner told me it was because with the smaller diameter cams they actually notice a loss in valve timing toward the rear of the block due to camshaft flex

Also, you'll see no mention of ANY lower end component with regard to valvetrain longevity, failure or stability.

http://www.aera.org/engine-professional/valve-train-stability/

Also, I was once in a NASCAR engine dyno room where tons of small block Chevy race parts were shelved. I noticed that the camshafts were larger diameter than those in production engines. The owner told me it was because with the smaller diameter cams they actually notice a loss in valve timing toward the rear of the block due to camshaft flex

- Joined

- Mar 21, 2012

- Messages

- 26,697

- Points

- 1,033

What part don't you get?

Somebody f'd up. Either way a light rod will NEVER cause valvetrain issues.

Bobby you said it was virtually impossible with quality controls that are in place to get a cam shaft with a defective lobe, the defective rod comparison was to show that with quality controls or not that anything can and usually will happen at some point. I never stated that a light rod could cause a valvetrain problem. I doubt a lobe caused the problem but with the little info we have who the hell knows.

Yes, I understand your point. I don't know how TRD balances their engines or how that could have been overlooked. Sure, we don't know exactly what is causing the JGR valvetrain issues, but we know what isn't causing them.Bobby you said it was virtually impossible with quality controls that are in place to get a cam shaft with a defective lobe, the defective rod comparison was to show that with quality controls or not that anything can and usually will happen at some point. I never stated that a light rod could cause a valvetrain problem. I doubt a lobe caused the problem but with the little info we have who the hell knows.

Nice article here on balancing...> http://www.fordmuscle.com/archives/2008/04/RotatingAssembly/ Balancing isn't rocket science. Nobody would have assembled a motor with one light rod on purpose. Which is why I believe someone screwed up.

We know the light rod and the valvetrain issues are not related.

As I said previously, it could be Matt over-revved the motor and floated a valve, or something in the geometry is off. They are probably using the lightest possible rated springs (tension).

More info on the development of Toytota's pushrod engine. Raises more questions though. they raised the height of the cam in the block..oh oh Bobby, the cam, because of it's location, could be part of the problem.

http://www.caranddriver.com/features/tundra-and-lightning-building-toyotas-pushrod-v-8-page-6

http://www.caranddriver.com/features/tundra-and-lightning-building-toyotas-pushrod-v-8-page-6

Yes, a lot of the time they are referring to rocker arms. From TRD's statement earlier in the week, they know exactly what failed and what caused it. I expect to see a little less HP out of the JGR cars this weekend. Denny traditionally runs well here, it will be interesting to see if the changes to the engines will affect his overall performance.We have also been aware for years that when they say valve spring its a catch all excuse so they don't have to reveal the real problem.

So your Google button IS workingMore info on the development of Toytota's pushrod engine. Raises more questions though. they raised the height of the cam in the block..oh oh Bobby, the cam, because of it's location, could be part of the problem.

http://www.caranddriver.com/features/tundra-and-lightning-building-toyotas-pushrod-v-8-page-6

There are more Toyotas running at the end of the race than there are in the garage.

well that answers your constant honking about the cam anyway. Yes it can be just the cam..although I never said that it was just that, but a combination of things.

No it isn't the camshaft, dammitwell that answers your constant honking about the cam anyway. Yes it can be just the cam..although I never said that it was just that, but a combination of things.

"...There have been 17 Toyota engine failures this season, but eight of those were built by Triad Racing Technologies, two by Racing Engines Plus and one by Pro Engineering that supply engines to lower-tier Toyota teams. Wilson said while TRD does supply unfinished engine blocks and heads to those builders, that's as far as the relationship goes.

"We have zero control, zero responsibility for those engines," he said. "There is no correlation between our issues and their issues. They may as well be Chevys and Fords. Other than having the same blocks and heads, that's as far as that goes."

Wilson said the valve train issues TRD has had are not unique to problems other engine builders have with other manufacturers. He said the steel springs that NASCAR stipulates teams must use are put through tremendous pressure, particularly on newly surfaced tracks where drivers have more car control and get on the throttle coming out of corners faster..."

could be the LOCATION of the cam is part of the problem. You act like you know what the problem is, I am saying it could be a number of things including the camshaft. At any rate here is something I didn't know below that Nascar makes all manufacturers do.

Note: Toyota is distancing itself from the other vendors as it says in the article Bobby has posted above. But if it is a basic design flaw that is common to all the engines they sell, and 17 engines blowing up to ME points to a design flaw.

NASCAR requires that all manufacturers make their engine blocks and other parts and pieces available to anyone who wishes to buy them. Although Toyota tightly controls its teams, it cannot stop a random racer from buying and running a Tundra. That's how Davis can continue to campaign Dodges while Dodge tries to flay him in court. That's how Toyota developed its own truck engine—by acquiring and studying the pieces of its competitors.

"We'd certainly like to have the ability to benchmark our competition like they have," GM Racing group manager Patrick Suhy said at Atlanta in March, "but we haven't been able to buy the Toyota stuff yet. There are various reasons. Some of them are reasonable and some of them—I don't know how reasonable they are. But I'm just saying we haven't been able to get any Toyota hardware yet."

"No, that's not true," says TRD president and CEO Jim Aust. "We actually sold a block and head, which are the primary components, to Dodge. And we recently have also received a request from Rick Hendrick, so we're selling an engine to him. The parts are available. We don't have a lot of them, so we're trying to make available those we do have to the people who actually want to race them."

Note: Toyota is distancing itself from the other vendors as it says in the article Bobby has posted above. But if it is a basic design flaw that is common to all the engines they sell, and 17 engines blowing up to ME points to a design flaw.

NASCAR requires that all manufacturers make their engine blocks and other parts and pieces available to anyone who wishes to buy them. Although Toyota tightly controls its teams, it cannot stop a random racer from buying and running a Tundra. That's how Davis can continue to campaign Dodges while Dodge tries to flay him in court. That's how Toyota developed its own truck engine—by acquiring and studying the pieces of its competitors.

"We'd certainly like to have the ability to benchmark our competition like they have," GM Racing group manager Patrick Suhy said at Atlanta in March, "but we haven't been able to buy the Toyota stuff yet. There are various reasons. Some of them are reasonable and some of them—I don't know how reasonable they are. But I'm just saying we haven't been able to get any Toyota hardware yet."

"No, that's not true," says TRD president and CEO Jim Aust. "We actually sold a block and head, which are the primary components, to Dodge. And we recently have also received a request from Rick Hendrick, so we're selling an engine to him. The parts are available. We don't have a lot of them, so we're trying to make available those we do have to the people who actually want to race them."

racer8

Team Owner

It done blowed up plain and simple.

Thats my expert opinion.

Thats my expert opinion.

FenderBumper

The "good old days" ??

Read here and see how virtually impossible it would be to have one defective lobe on a camshaft...> http://www.dragzine.com/features/shop-tours/comp-cams-shows-how-a-camshaft-is-made/

Cams are measured and inspected as part of quality control before they leave the manufacturer. If that isn't enough, IF a camshaft had one lobe larger than the rest, it would be noticed when the valves were adjusted during engine assembly in the form of coil bind.

Yep. VIRTUALLY impossible. why are you being such a knuckle head about this? I proved out for you how a DEFECTIVE cam can indeed lead to a failed valve, which was the question you asked.

It's over. Leave it alone.

Oh my..as the cam turns..tune in tomorrow for the next episode...My engine done blowed up..again! channel splode 99.5 F.M. on your radio dial, or kaboom 1170 A.M.

KevinWI

Oldest Operating Motor Speedway In The World

HoneyBadger

Kelsey Mitchell fan account

+1 for the "Thriller" reference. Smooth Criminal and Thriller are the greatest music videos of all time.