O

OriginalRamcharger

Guest

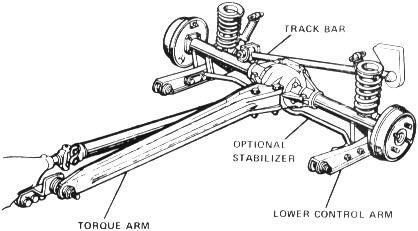

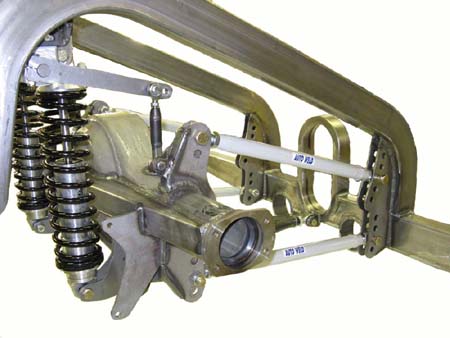

This is just a little teaser for experienced dragracers. As you walked through the pits, you saw more than a few ladder bar cars.These cars have, of course, two sturdy ladder bars that are attached to the axle housing and which pivot at their front attachment points. Okay, here's the question. All the ladder bar cars you saw had two ladders. Now, have you ever seen a car with only one ladder? I'd venture to say, if you're of any age at all, you've seen hundreds of cars with only one ladder. Don't you remember? Okay, here's the answer. Consider the tube which surrounded the driveshaft on the early Fords and Chevys. Wasn't that firmly attached to the axle housing and didn't it pivot at the front? Of course it did. It was a single ladder bar. You could do the same sort of thing with an open driveshaft. Just attach a single ladder at the side of the driveshaft. Which side? Well, if you'd like to cancel the unloading of the right rear, you'd want it offset to the US passenger side. How much offset? If you offset it by the wheelbase divided by the axle ratio, you'd be pretty close. Sorry to disturb you. I just enjoy nudging people outside the box.