You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Storage building

- Thread starter KTMLew01

- Start date

KTMLew01

Team Owner

Really need to make myself buy a holesaw set. And a jigsaw.

Magicmiler

Team Owner

I ran a nut attached to string and tipped my PVC at an angle to let the string go all the way to the other end. Then I taped my wires to the string and pulled thru the PVC. Worked pretty good. Looks like you did alright too...This is like shoving wet spaghetti up a wildcats arse. Wanted to put two cables they it but that ain't happening. Bought 1 inch PVC for 10/2--220 cable. Whole bunch easier to work with. Sun popped out so taking break till this evening. Have to dig trench. My back hates shovel work.

KTMLew01

Team Owner

My concern on burying conduit is Spectrum cable runs thru there. Have to gently dig until I locate it. Orange cable.

KTMLew01

Team Owner

I might try the old school dowling rod thing to see if i can find cable. Great thing about retirement and no significant other is I can do whatever I want at my own pace. Surprised I felt great all day yesterday and didn't get tired or sleepy like I usually do. I'm gonna wait till tomorrow for the stuff I ordered. Wood bits so can drill decent holes and couple other things.

KTMLew01

Team Owner

Amazon says stuff will be delivered this afternoon. We shall see.

KTMLew01

Team Owner

Amazons shipping info has been fubar for months. Order=instant email YOUR PACKAGE WILL BE DELIVERED TOMORROW! How could they possibly know if it hasn't even shipped 16 hours later? This one said delivery between 11;30Am & 4PM today. Now says by 10PM today. Ahhhh bidder, bidder, bidder.

KTMLew01

Team Owner

Package just arrived! Guess I just need to whine?

KTMLew01

Team Owner

KTMLew01

Team Owner

Need to get two more square boxes. One more for under porch and another for inside where Yellow Romex goes thru 2x4/floor. Ground is too hard to dig right now without taking chance of cutting TV cable. Washer/dryer is up and running right now. Was going to run 110 for outside outlets off existing circuit but found enough 12/2 to run to breaker box. Will be on separate 20A circuit.

These new style wire nutz keep hurting me. Punched a hole in my melon with needle nose. You would think when the blood level drops down to the hole it would quit leaking. But nope. Was running like a facet. Place looks like an episode of of a crime drama. Of course no Band-Aids. Just used toilet paper and about a minute or so of pressure to stop the leak. Finished the 220 wiring, then went to Food Lion and got Band-aids. If you gonna be dumb, gotta be tough, amiright?

These new style wire nutz keep hurting me. Punched a hole in my melon with needle nose. You would think when the blood level drops down to the hole it would quit leaking. But nope. Was running like a facet. Place looks like an episode of of a crime drama. Of course no Band-Aids. Just used toilet paper and about a minute or so of pressure to stop the leak. Finished the 220 wiring, then went to Food Lion and got Band-aids. If you gonna be dumb, gotta be tough, amiright?

KTMLew01

Team Owner

KTMLew01

Team Owner

Hmmmm? The divot in my melon? I did this before not long ago. Don't remember exactly what I was doing but exactly same result with same pliers. This time almost created an entrance & exit hole. Bled like a stuck hog. Hole is bigger than pinkie fingernail. OUCH!

KTMLew01

Team Owner

KTMLew01

Team Owner

Need to tear the bench out. That's where my big toolbox will fit. Will tidy up the wiring when bench is out of the way. Made sure the needle nose were faaaaar away. Need to buy another 30Amp double pole breaker. The one I had doesn't seem to fit box correctly. Doesn't snap in fully. Now I have to figure out what to do with all the crap on/under the bench before I can move on. I probably have enough buckets to put the stuff in? Then put it on trailer temporarily? Temporarily is a problem for me...

Porch is running over with "temporarily"...

Porch is running over with "temporarily"...

Attachments

KTMLew01

Team Owner

Oh...all the wiring I did today was with old-school wire nutz. I give up on the Wago connectors. They hurtz me too many times.

KTMLew01

Team Owner

Removed bench and moved sheeting over so can use existing shelves. Really need to find someone to do roofing. I'm too chickensheet. With my back spasms and occasional vertigo I'm almost guaranteed to fall off on my needle nose pliers.

Need trailer to throw old shingles on as removed. Need to unload trailer. Contents of trailer will basically fill the shed. Maybe I can learn to juggle?

Need trailer to throw old shingles on as removed. Need to unload trailer. Contents of trailer will basically fill the shed. Maybe I can learn to juggle?

Attachments

KTMLew01

Team Owner

KTMLew01

Team Owner

I know what I have to do. I just don't wanna. Put ALL the sheeting outside. Stuff all my toolboxes in shed then slide the sheeting back in. REALLY need to just do porch roof. I CAN put some old plywood down and put some of the stuff on trailer on it and cover with tarp beside shed. Then park trailer right against side of porch so can throw shingles on. What's pathetic...somebody with carpenter skills could do the porch start-to-finish in an hour or so. It's 4 sheets of plywood and peel & stick roofing. I'm gonna say max of 1/2 hour to have naked rafters. Only question is where old roofing was glued/screwed/magic welded to trailer roof. Have a grinder with wire brush to clean roofing putty/cement off trailer roof. Enough roofing to go clear across trailer if it had to. Have metal flashing if needed. Building supply right across road if anything needed. I just need to find a couple guys that would like to make $100 in an hour. But anyone with the skills probably makes 500 for an hour doing this type of job. Whaaaaa!

KTMLew01

Team Owner

KTMLew01

Team Owner

Phone is dying. Sometimes take a picture and it takes shutter 20 seconds to do it's thing. Either miss the picture completely or end of with blurring crap. Plus it's gotten so it doesn't want to respond. Tried to delete some pics. Just keeps going back to same picture.

KTMLew01

Team Owner

KTMLew01

Team Owner

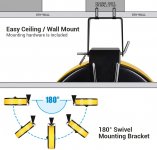

Of course I forgot to unplug the fan...big box moved to right just enough to slide between. I'll add a switched box to back wall so I don't have to mess with fan. Would like to get a small AC to stick thru back wall. Have two vents to put in walls.

KTMLew01

Team Owner

Spent about 3 hours this morning sorting thru stuff. Really need to put another layer of sheeting on floor. Big box doesn't want to roll. Plan to move big box against right wall once sheeting is out/used. Only big box & tool cart will stay in shed. Other stuff will go on porch once it's cleaned off and barn roof is done on shed. Neighbor sleeps 25 feet from where I'm banging stuff around & works nights. He just came home around 8AM. So I try to keep the noise down in afternoons. Plus it's hot as hades afternoons. Put everything back in tool cart except pliers. Gonna wear a helmet for those. But we be gaining.

Attachments

KTMLew01

Team Owner

Landlord passed around 12:30 this afternoon. Cancer.

Here's hoping the lady who passed away managed to fulfill her promise to you re: living quarters.

Just curious, but why such large tool boxes if you are retired? Looks to me like you could reduce some of your tool inventory and utilize space to a better purpose than hanging onto tools and over sized boxes when your purpose is to enjoy life and not be working on, over and/or under mechanical conveyances.

I had three tool boxes, not the size of the yours but one base unit and top section plus a second large work bench sized box, all filled with everything I could think was needed to perform any job encountered.

When we sold our house in Raleigh and relocated to Florida, we took only what would fit in an 8 x 12 enclosed trailer. Of course, my tool boxes came with us but it now seems as if all they do is take up space and the few tools I use from them would fit in a fishing tackle box and even those are rarely used. I have a hobby space or man cave, call it what you will, it is actually an enclosed lanai or Florida room. Still, those damn tool boxes are like new, always treated with love and affection and also, after multiple rearrangements to utilize limited space, came to the realization these tool boxes are in fact my albatross and will soon be gone. It took me a long time to realize their functionality at this stage of my life was 99% non-existent.

Just the ramblings of an older man who has endured the reluctance to let go of one more thing that, along with my pickup truck and pecker, constitute my manhood.

Just curious, but why such large tool boxes if you are retired? Looks to me like you could reduce some of your tool inventory and utilize space to a better purpose than hanging onto tools and over sized boxes when your purpose is to enjoy life and not be working on, over and/or under mechanical conveyances.

I had three tool boxes, not the size of the yours but one base unit and top section plus a second large work bench sized box, all filled with everything I could think was needed to perform any job encountered.

When we sold our house in Raleigh and relocated to Florida, we took only what would fit in an 8 x 12 enclosed trailer. Of course, my tool boxes came with us but it now seems as if all they do is take up space and the few tools I use from them would fit in a fishing tackle box and even those are rarely used. I have a hobby space or man cave, call it what you will, it is actually an enclosed lanai or Florida room. Still, those damn tool boxes are like new, always treated with love and affection and also, after multiple rearrangements to utilize limited space, came to the realization these tool boxes are in fact my albatross and will soon be gone. It took me a long time to realize their functionality at this stage of my life was 99% non-existent.

Just the ramblings of an older man who has endured the reluctance to let go of one more thing that, along with my pickup truck and pecker, constitute my manhood.

KTMLew01

Team Owner

We are in complete agreement. Covid shut me down as for dealing with strangers. As for selling tools...you can probably make as much selling most for scrap. You paid $220 and guys offer $30. I'll eventually sell some this summer. Not so much as financial windfall but more to align with your thoughts. I don't need them. IF I ever get organized, thought about cruising thru a bunch of shops around lunch time and see if i can sell some that way. It would be a GREAT opportunity for a young tech to get set-up pretty darned cheap if they could buy the toolbox with all tools. The big box was only $599 new I think? It's about 4 years old. I have a bunch more old Craftsmen boxes too.Here's hoping the lady who passed away managed to fulfill her promise to you re: living quarters.

Just curious, but why such large tool boxes if you are retired? Looks to me like you could reduce some of your tool inventory and utilize space to a better purpose than hanging onto tools and over sized boxes when your purpose is to enjoy life and not be working on, over and/or under mechanical conveyances.

I had three tool boxes, not the size of the yours but one base unit and top section plus a second large work bench sized box, all filled with everything I could think was needed to perform any job encountered.

When we sold our house in Raleigh and relocated to Florida, we took only what would fit in an 8 x 12 enclosed trailer. Of course, my tool boxes came with us but it now seems as if all they do is take up space and the few tools I use from them would fit in a fishing tackle box and even those are rarely used. I have a hobby space or man cave, call it what you will, it is actually an enclosed lanai or Florida room. Still, those damn tool boxes are like new, always treated with love and affection and also, after multiple rearrangements to utilize limited space, came to the realization these tool boxes are in fact my albatross and will soon be gone. It took me a long time to realize their functionality at this stage of my life was 99% non-existent.

Just the ramblings of an older man who has endured the reluctance to let go of one more thing that, along with my pickup truck and pecker, constitute my manhood.

The problem with that idea is peer pressure. Everyone pushes the young guys onto the tool truck. Worked with an 18 y/o that was given $9000 in credit right out of high school. Spent 7K on a box. Maybe $1000 on tools. Idiotic. I'd be really surprised if he's still in the business and that was maybe 5 years ago. I tried to get him to buy a Husky box. Yes it's cheap junk. But it'll last 5 years with some common sense. THEN buy a USED tool truck box. Work your way up. But that's not the way it's done now.

Husky 80 in. 10-Drawer Garage Workcenter, 24 in. Deep with Side Locker, Matte Black HOTC8010BB1S - The Home Depot

The Husky 80 in. x 10 drawer tool box Garage Workcenter and Side Locker unit is a heavy duty, 19-Gauge steel, 3 piece tool storage unit that is rated for 3,000 lb. loading capacity. The 24 in. D garage

www.homedepot.com

The above will still be worth nearly same price 5 years from now. Again though, using common sense by NOT loading 350lbs in a 200lb top drawer and breaking the darned thing. Peer pressure and impatience.

KTMLew01

Team Owner

Still waiting for funeral arraignments. The son that's been handling things is a straight shooter. I won't take possession of the dwelling until her daughter, which had a liver transplant in 2013, passes. So could be 10 or more years although I suspect she'll drink herself to death fairly soon. Alcoholics are always alcoholics. She's moving back to the beach where the party never ends. But it's her life. She might outlive me?

As I mentioned before...whole thing is ghoulish. If I could I would leave the country before the zhit really hits the fan. Philippines is cheap enough but I don't have a nestegg to support me if things went sideways. So I'll stay here until the other shoe drops. We are currently IN a civil war whether you want to hear it or not. The 2022-2024 elections WILL determine if we stay a Democratic Republic or become an Autocracy. Somebody like DeathSantis or Kristi Noem could be "your leader" for next 30-40 years. But I digress...as usual.

As I mentioned before...whole thing is ghoulish. If I could I would leave the country before the zhit really hits the fan. Philippines is cheap enough but I don't have a nestegg to support me if things went sideways. So I'll stay here until the other shoe drops. We are currently IN a civil war whether you want to hear it or not. The 2022-2024 elections WILL determine if we stay a Democratic Republic or become an Autocracy. Somebody like DeathSantis or Kristi Noem could be "your leader" for next 30-40 years. But I digress...as usual.

KTMLew01

Team Owner

KTMLew01

Team Owner

Statement of Concern

Democracy scholars urge members of Congress to pass national voting and election administration standards.

KTMLew01

Team Owner

Working on finishing the air compressor repairs. These upright compressors are just waiting to fall over. The regulator sticks out past the tank and gets whacked. That broke the mount. The #1 issue with these compressors is the supply tube from head to tank. Aluminum tube with no flexible section. So the compressor needs to be mounted solidly but not TOO solid. Has three rubber things to isolate vibration.

I have another mount. Problem is the pulley on motor has to come off. Apparently it is a smooth bore pulley which is pressed on splines which broaches the splines in the pulley. SHE BE TIGHT! No way to get the pulley off without destroying it. Pulley is close to $40. If spending that also need a flexible discharge tube which is $75ish bucks. How much would you want to invest in an oil-less compressor? NOT VERY MUCH!

So we be patching! JB Weld the broken piece in place then add a metal tab to support it! I hope. I wanted a piece of L shaped meatl about 6" lng to run full length. Can't find anything. Can't be angle iron as too think. Has to be slid up behind flywheel to allow attachment.

I have another mount. Problem is the pulley on motor has to come off. Apparently it is a smooth bore pulley which is pressed on splines which broaches the splines in the pulley. SHE BE TIGHT! No way to get the pulley off without destroying it. Pulley is close to $40. If spending that also need a flexible discharge tube which is $75ish bucks. How much would you want to invest in an oil-less compressor? NOT VERY MUCH!

So we be patching! JB Weld the broken piece in place then add a metal tab to support it! I hope. I wanted a piece of L shaped meatl about 6" lng to run full length. Can't find anything. Can't be angle iron as too think. Has to be slid up behind flywheel to allow attachment.

KTMLew01

Team Owner

A poor design IMO. No reason the Tang/slot deal couldn't have been full length of bracket. It's supported on 3 "tabs" of steel plate on tank with rubber isolators. The pen is in the pocket the rubber isolator slide in. Will add a steel L-bracket to add support. Just not a lot of places to bolt thru.

Attachments

KTMLew01

Team Owner

Can't use anything thicker. Will have to trim them to make it fit. Bolt on with 1/4" bolts. I'm hoping I have better luck with JB Weld on this repair. Never had any luck with it. Just doesn't get hard. Kinda gummy. Will see tomorrow. Used the old-style which takes 24 hours to set-up.

Attachments

KTMLew01

Team Owner

This is the spare compressor bracket. You can see the damage to the pulley where I tried to pull it. Used a new bearing separator. No bueano. I CAN use any methods included nukes to get this one off as long as bracket isn't damaged. Doesn't help me get the one off the good motor.

Attachments

KTMLew01

Team Owner

Here's hoping the lady who passed away managed to fulfill her promise to you re: living quarters.

Apparently they buried landlord day after she passed. Never told me about it. Her daughter with liver transplant didn't go. Not sure why. Maybe Covid concerns?

I suspect they struck a deal with park owner. Three of us are going to start paying him the rent then he'll take his split and pass on the rest to them. My guess is he will get the trailers whenever the other shoe drops. But he's 82. I asked him what arraignments were set for when his time comes. His daughter lives right across the road. Goes to wife then daughter. He said I don't have to worry about having to move. I don't trust anyone to do what they say. Money talks.

As The Stomach Turns continues.

KTMLew01

Team Owner

Looking for the bracket to hang extension cord reel. I know I put it somewhere. But somewhere seems to have moved. Going to cut/trim/hack the L bracket for compressor later. Got too hot. Once compressor works, need to testicle nail guns. If THEY work...have to do porch roof. Ummm? Actually will lay-out/cut 2x4's for barn style rafters while have sheeting to lay it out on. Nail up halves of rafters so can easily store them. Then it's porch roof time. Since porch is 15-20-25? years old going to run a 2x6 down center and block it up with sister'd 2x4's to make sure it doesn't fold up with me on it. The structure looks fine, but? Now that trailer is available also frees up tarps so can move everything off porch and cover it if necessary. Man I wish I could find the cord reel bracket.

Attachments

KTMLew01

Team Owner

KTMLew01

Team Owner

Now that I look at the specs on that reel it's not much good anyway at 10Amp rating. Might as well just use regular cord.

Amazon product ASIN B07YKDMFQR

I think, only place I had it mounted, already had a bracket on the wall. Don't believe I ever used the one that came with it. Minor issue.

Amazon product ASIN B07YKDMFQR

I think, only place I had it mounted, already had a bracket on the wall. Don't believe I ever used the one that came with it. Minor issue.

Attachments

KTMLew01

Team Owner

Looks like rain is coming. Put everything away so I don't have to chase the EZ-UP all over the place. Plan is to measure the area the L-bracket will cover, grind area smooth (has some casting crap sticking out), figure out where I can drill holes in aluminum bracket with access for nut on back. Probably drill 1/4 holes in aluminum and 5/16 in steel, so it has some adjustment. I'll be really surprised if the piece I JB Welded on doesn't fall off after some vibration. Really don't like that stuff. Have some Devcon here somewhere.

KTMLew01

Team Owner

Next attempt I'll park truck off the side of building so can use outside outlet. Need to run 4" grinder and a bit worried about using an extension cord. Whole reason I wired in that outlet.

KTMLew01

Team Owner

Using truck as vise mount. Have vise on 2x8 & clamp it to the bed. If I every get shed sorted and sell big toolbox I'll build a proper bench to mount vise. Fell asleep during 3rd stage of race. Slept till 11:30ish. Now wide awake.